Warehousing Data

Traditional databases and warehouses were created for 20-year-old workloads, sufficient at the time, but these systems can no longer meet the demands of modern businesses with the volume, speed, and data demand of users. IT departments face a great challenge.

Businesses want to analyze the data load exponentially in real-time or near real-time. This is why our vision is to be an important support in the market, through data engineering at the service of our customers needs.

We develop Data Warehousing using tools such as Machine Learning, Big Data, Artificial Intelligence, Data Processing, among others.

In this way, we generate greater opportunities, competitiveness, and sucessful.

Warehousing For Stock

In today's industrialized and competitive world, new challenges are imposed. Factors such as time, efficiency, and effectiveness, have become essential in process optimization.

The concepts of inventories, cost optimization, operation times, and inventories policies, have taken great importance today and are being adopted by a branch of robotics.

Automated processes can be applied not only in the intelligent and autonomous distribution of goods, products, or elements of an organization; It can also contribute to the information administration and control.

It is possible to integrate robotics, for example, in health entities, through supervision that optimizes the administration of medicines and supplies in collection centers to facilitate the rapid and effective management of these elements.

Warehousing Vehicles

There are several factors to consider before purchasing this intelligent merchandise storage and distribution system:

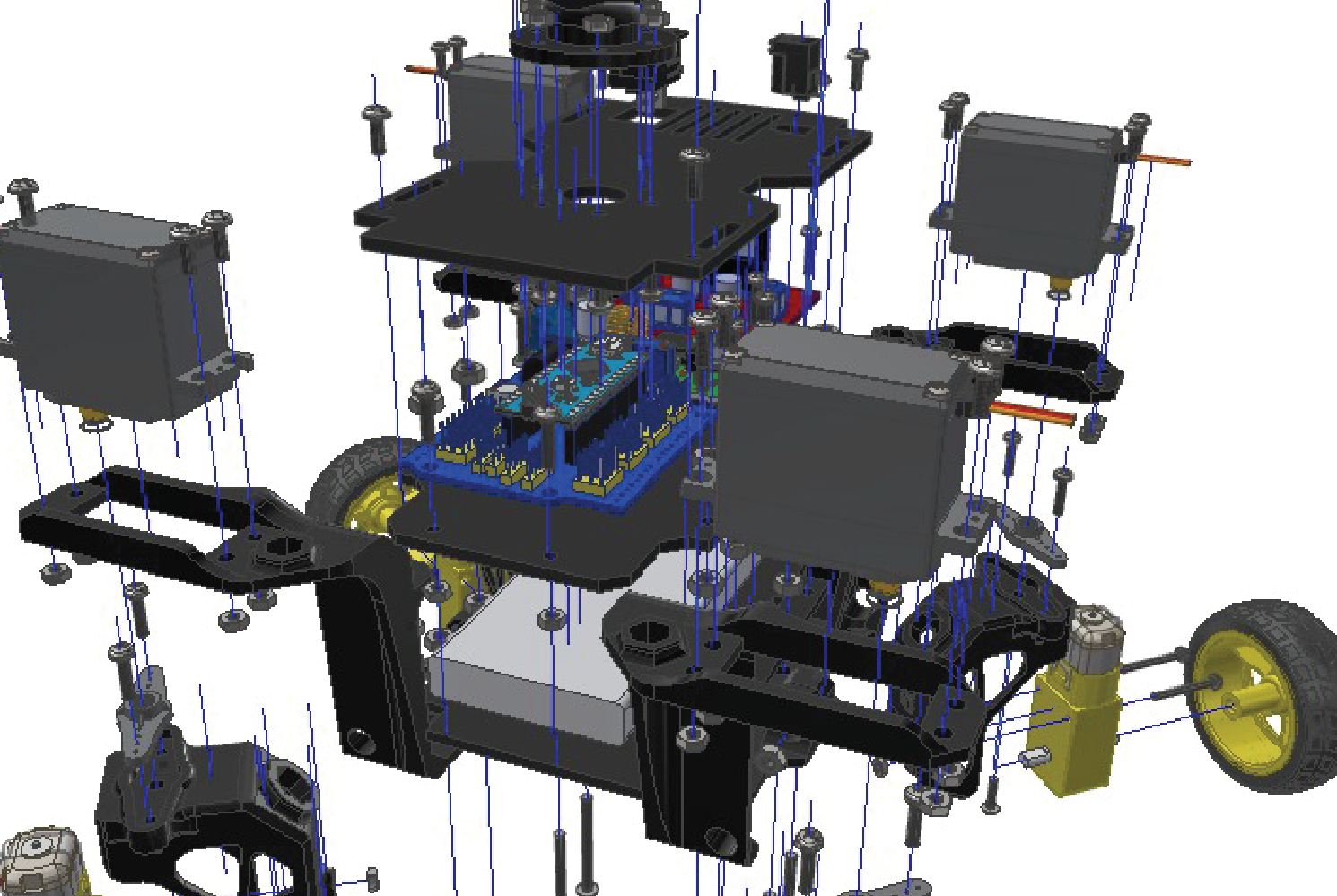

There are a variety of vehicles available. Some move by following markers or cables on the ground. Others use vision (camera-based images), magnetic guidance, or laser guidance for navigation.

The type of vehicle that best suits the required task should be chosen. For example, AGV (Automated Guided Vehicles) of light load, tugboats, pallet trucks, etc.

The software, if the AGV program can communicate with existing systems and equipment. Also, if this program is simple and easy to use.

Other factors to consider:

Battery charging: there are various options such as battery change, automatic charge, automatic battery change, etc.

Maintenance

Cost: determining your requirements can help you find the system that best fits your budget.

Why you should choose autonomous vehicles for storage?

Most companies must pay the necessary payroll to operate rudimentary machinery but if they choose an AGV system, they will save a lot of money.

This autonomous system locates products and can easily track them in a limited time, reducing costs.

Constancy of operation: AGV-type systems enable predictable travel with efficient constant speed.

Unification: choosing an AGV with compatible software facilitates integration with other equipment within the facilities.

Characterization: the capabilities of some AGVs can be customized to suit the operating environment and production needs.

Practicality: AGVs can be installed in existing facilities with little or no modification to the structure or storage systems.

read more material-hanling-warehousing

read more material-hanling-warehousing